Getting The Sheroz Earthworks To Work

Getting The Sheroz Earthworks To Work

Blog Article

What Does Sheroz Earthworks Do?

Table of ContentsSheroz Earthworks Can Be Fun For AnyoneSee This Report on Sheroz EarthworksNot known Details About Sheroz Earthworks An Unbiased View of Sheroz EarthworksRumored Buzz on Sheroz Earthworks

For any earthwork contractor, it is important to execute deal with high quality, precision, and on time. Making use of maker control in work makers enables maximizing the various stages in the earthwork process, from preparing to the maintenance phase - topcon laser levels. The machine control system helps the equipment operator in attaining the target aircraft quickly and quicklyThe machine control system overviews the operator with centimeter accuracy. Remote support conserves time and money, as it reduces downtime in jobsites.

The smart Trick of Sheroz Earthworks That Nobody is Discussing

Extra training and guidelines are always readily available over remote assistance when needed. The earthmoving market has utilized our field-proven services given that the very early 1990s. Our system's components are thoroughly made to withstand the harsh problems of building and construction sites. Comparison of the same job implemented using machine control versus the standard technique reveals that, generally, the traditional strategy calls for 50% more time to achieve the exact same task as the technology-assisted method. https://lwccareers.lindsey.edu/profiles/5240299-floyd-overbeck.

Appears excellent, right? Go into the Xsite equipment control system; it's here to give you with a considerable benefit when collaborating with earthmoving equipment. Discover exactly how Xsite Equipment Control can enhance your productivity and make certain job security! We understand that learning a brand-new innovation could feel like a drag, yet do not worry! Our friendly and specialist regional assistance services have obtained you covered, making sure that you can keep functioning smarter without disruptions while at work! Through remote support, your neighborhood Xsite dealer can supply guidance or troubleshooting without having to visit the site! What sort of excavators does equipment control fit? Xsite Machine Control systems can be mounted to any excavator from mini excavators to large mining excavators.

Exactly how does device control work? In 2D systems, the maker is furnished with calibrated disposition sensors. These sensing units are placed on the pre-determined parts of the equipment in excavators the sensor are typically installed to the framework, boom (or booms), miner arm and to the quick coupler - topcon laser level. By utilizing the information received from these sensors the system can compute the precise setting of the excavators pail tip in relevance to a recommendation factor.

The system is extremely simple to learn the basics can be educated in under one hour of training. How does the remote assistance job? A cordless net link makes it feasible to establish a remote connection in between the machine control system and the solution.

The Main Principles Of Sheroz Earthworks

What type of data formats Xsite systems assistance? Xsite Maker Control systems sustain open basic file layouts, allowing seamless details circulation from one system to one more. Sustained file styles: 2D-Maps: DXF Point documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Designs: DXF, XML What elements are mounted on my device? Depending upon your selection of system (with or without positioning, i.e - trimble gps., 2D or 3D), your maker is furnished with disposition sensing units, a controller unit, and a display/operating panel.

Lots of hardware and software services exist to assist establish a machine's existing position on the earth and contrast it with a preferred layout surfaceand building and construction drivers can do even more to utilize the advantages. Equipment control is the use of various positioning sensing units and a display to supply the operator with a reference between the placement of the bucket or blade and the target grade.

Depending on the setup, maker control systems can supply the operator with a simple visual overview to pail or blade position, or can instantly relocate the blade to grade by speaking with the machine's hydraulics - https://qualtricsxmkpyy9kbs2.qualtrics.com/jfe/form/SV_3IOcfD5rXwnI6x0. There are device control systems available for almost any equipment: , dozers, excavators, soil and asphalt compactors, scrapers, trimmers, milling machines, and pavers

The Only Guide for Sheroz Earthworks

Some advantages include decreased rework, improved task efficiency, and reduced surveying expenses. Machine control can likewise assist enhance efficiency and minimize general costs. This innovation is altering the means the building market works. Construction tools without device control will certainly become a point of the past and the benefits gained from it will be countless.

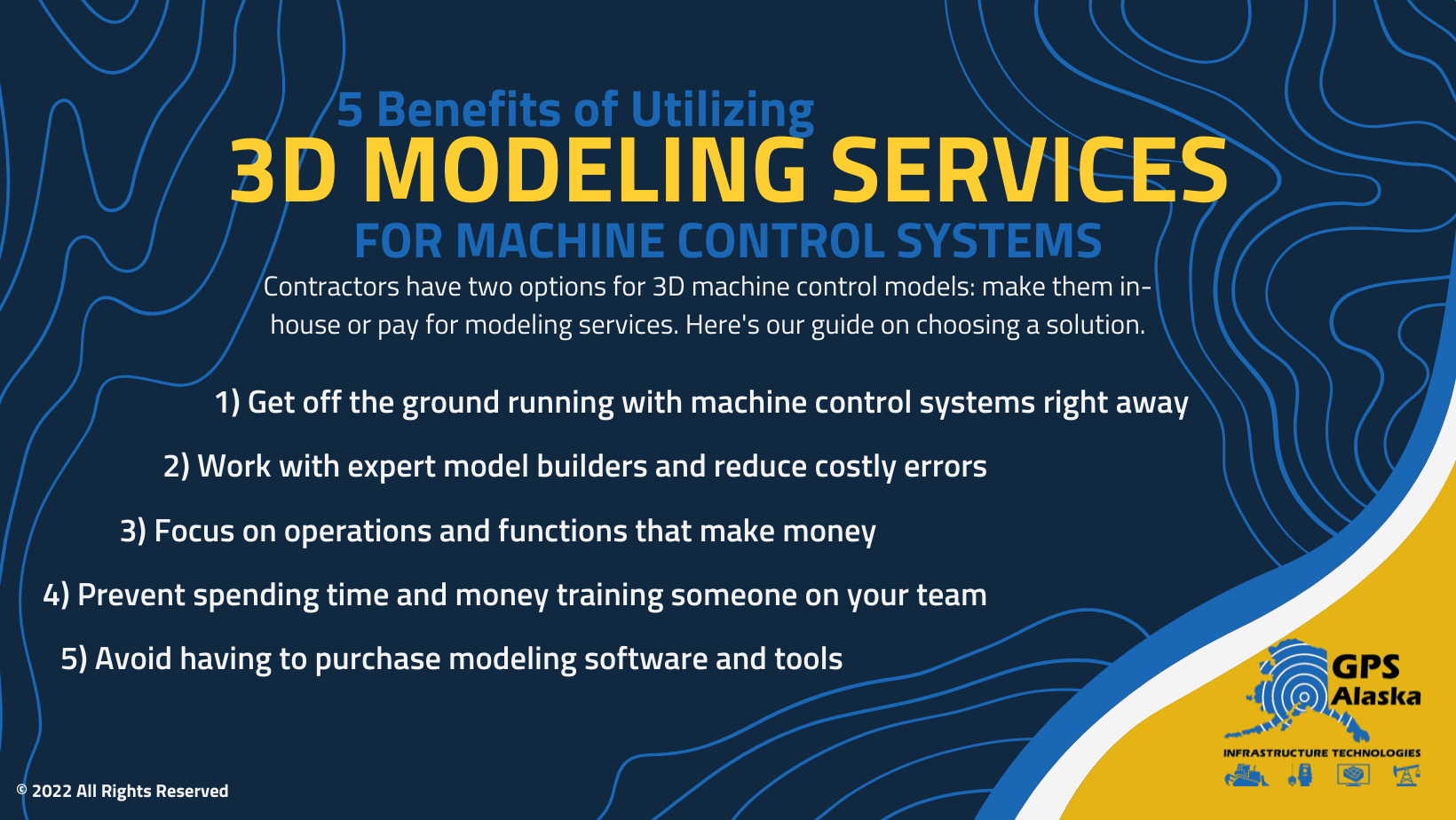

Trimble device control systems offer a myriad of benefits to any person that utilizes earthwork machinery and, at EarthCalc, we can supply you with 3D apply for your maker control-enable tools. Not exactly sure if equipment control is worth the Discover More Here cost? Take into consideration the following reasons you need to consider this alternative.

Making use of general practitioner lined up with your 3D style files, these systems essentially ensure that you will remove or position the right amount of material at the building site. On the majority of building and construction sites, remodel is an usual and frustrating truth, however with Trimble equipment control, you can remove the requirement for rework.

Sheroz Earthworks - Truths

Frequently, with Trimble device control, you can remove excess tools at a details task site. For circumstances, a task that could have needed the use of three or four pieces of excavating devices currently might require only 2 items of tools to achieve the same job in less time. This allows you to relocate your devices to one more work site and deal with multiple jobs at once.

Report this page